A brief explanation of bitumen emulsions

Bitumen emulsions provide an environmentally-friendly and user-friendly option to handle and process bitumen as a binding agent. There are anionic and cationic bitumen emulsions. The latter is generally used in road construction and road maintenance in various applications.

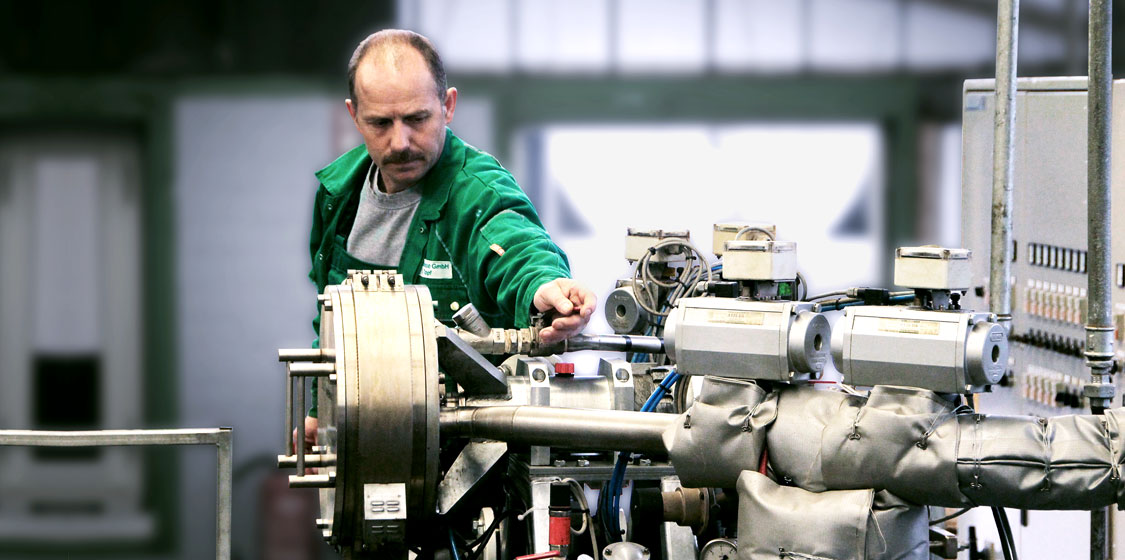

The manufacturing process

Our facilities are among the most modern manufacturing facilities in Europe. The manufacturing processes are fully automatic and feature computer-aided monitoring in a closed inline system for the specified composition.

When manufacturing begins, the water line is stabilized until a constant quantity of components being added is achieved. Chemical agents are added in small dosages via the water line based on the corresponding formulation. Flow meters monitor the process here, and their measurements are constantly processed within the system. If the water line is flowing properly, the bitumen line meets the water line in the colloid mill, which is at the core of the manufacturing facilities. In the colloid mill, the bitumen particles are broken down by spinning discs and dispersed into the water, at which point the blend is considered a bitumen emulsion. When the bitumen emulsion leaves the colloid mill, it is approximately 90°C and will initially be cooled down to approximately 60°C in the first stage. The subsequent cooling stage drops the temperature further to ≤ 30°C, which represents an important requirement for specific bitumen emulsions for manufacturing DSK. There is a display in the control center to monitor the manufacturing processes. The employee in charge is able to respond immediately to any noticeable problems. If an issue occurs and there is no reaction, the system is configured to first signal an acoustic alert. If there is still no reaction, the emergency stop is triggered automatically.

Adding latex is a type of polymer modification and is done during the manufacturing process. It is also possible to add latex after manufacturing or to use a polymer-modified source bitumen (PmB).

Once manufactured, bitumen emulsions are put into interim storage in suitable storage containers until they are prepared for delivery to the customer. We ensure strict separation of our storage facilities, including piping connections and loading/unloading stations, to prevent impurities occurring in the various sensitive classes or classes that may react to one another. A product quality assurance check is performed as part of the factory production control before the bitumen emulsions are released for loading and shipping.

Handling on-site

Bitumen emulsions can be handling at the project site using specialized equipment depending on the type of application. An important factor is the choice of mineral. In terms of the physical process, a cationic bitumen emulsion is “broken” by the mineral. The positively charged bitumen emulsion interacts with the negatively charged mineral and come together through the electrical attraction. The bitumen emulsion breaks, i.e. releases water, and coats the mineral with the bitumen particles.

We want to point out an important fact here. Problems when applying the specific product can develop if the grading of the relevant mineral has a slight charge, a neutral charge, an aggressive charge, or no charge at all. It will mean that the breaking process, i.e., the attraction between the bitumen emulsion and mineral, cannot take place properly.

Learn more about critical factors:

+49 (0)3622 40733-0